What is PLA?

- Share

- From

- Sanle

- Issue Time

- Sep 22,2020

Summary

Polylactic acid is a polymer obtained by polymerization of lactic acid as the main raw material. The raw material source is sufficient and Renewable.biodegradable bottle manufacturers in China.

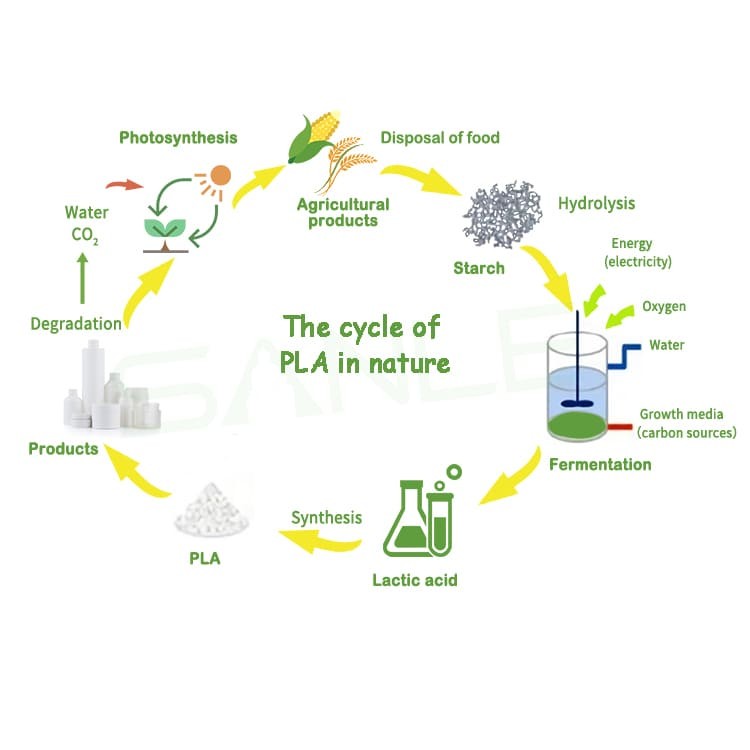

Polylactic acid is also called polylactide and belongs to the polyester family. Polylactic acid is a polymer obtained by polymerization of lactic acid as the main raw material. The raw material source is sufficient and renewable. The production process of polylactic acid is pollution-free, and the product can be biodegraded to realize the circulation in nature, so it is an ideal green polymer material. Polylactic acid (PLA) is a new type of biodegradable material. The starch raw material extracted from renewable plant resources (such as corn) is fermented into lactic acid, and then converted into polylactic acid through polymer synthesis. Sanle is biodegradable plastic bottle manufacturers,let us learn more information.

Advantages of polylactic acid (PLA):

1. Polylactic acid has excellent biodegradability. It can be completely degraded by microorganisms in the soil within one year after being discarded, generating carbon dioxide and water, and causing no pollution to the environment. Truly "derive from nature, attribute to nature"!

According to news reports, the global temperature will rise to 60°C in 2030. Common plastics are still treated by incineration and cremation, causing a large amount of greenhouse gases to be discharged into the air, while polylactic acid is buried in the soil and degrades. Carbon dioxide enters the soil organic matter directly or is absorbed by plants, and will not be discharged into the air and will not cause the greenhouse effect.

2.Polylactic acid is suitable for various processing methods such as blow molding and injection molding. It is easy to process and has a wide range of applications. It can be used to process various food containers, packaged foods, fast food lunch boxes, non-woven fabrics, industrial and civilian fabrics from industry to civilian use. And then processed into agricultural fabrics, health care fabrics, wipes, sanitary products, outdoor anti-ultraviolet fabrics, tent fabrics, floor mats, etc. The market prospects are very promising. It can be seen that its mechanical and physical properties are good.

3.The basic physical properties of polylactic acid (PLA) and petrochemical synthetic plastics are similar, that is to say, it can be widely used to manufacture various application products. Polylactic acid also has good gloss and transparency, which is comparable to films made of polystyrene, and cannot be provided by other biodegradable products.

Sustained-release packaging

4.Good compatibility and degradability. Polylactic acid is also widely used in the field of medicine, such as the production of disposable infusion equipment, non-dismantling surgical sutures, etc., and low-molecular-weight polylactic acid as a drug sustained-release packaging agent.

Tensile strength and ductility

5.Polylactic acid (PLA) has the best tensile strength and ductility. Polylactic acid can also be produced by various common processing methods, such as melt extrusion molding, injection molding, blown film molding, foam molding and vacuum molding. It has similar forming conditions as the currently widely used polymer, and it also has the same printing performance as traditional films. In this way, polylactic acid can be made into a variety of application products in response to the needs of different industries.

Safety of this decomposable

6.When polylactic acid (PLA) is incinerated, its combustion calorific value is the same as that of incineration paper, which is half of that of traditional plastics (such as polyethylene), and the incineration of polylactic acid will never release toxic gases such as nitrides and sulfides. . The human body also contains lactic acid in the form of monomer, which shows the safety of this decomposable product.

7. Polylactic acid (PLA) film has good air permeability, oxygen permeability and carbon dioxide permeability. It also has the characteristics of odor isolation. Viruses and molds are easily attached to the surface of biodegradable plastics, so there are concerns about safety and hygiene. However, polylactic acid is the only biodegradable plastic with excellent antibacterial and antifungal properties.

Today, when resource conservation and environmental protection are increasingly valued, can plastic be replaced and upgraded? The widespread use of degradable biomass material-polylactic acid (PLA) can not only alleviate the resource dependence caused by the "oil crisis", but will also completely eradicate white pollution.

Sanle Plastics offering one-stop boutique service. We support you throughout the entire process from design selection and development all the way through to after-sale service.

As professional biodegradable packaging manufacturers, SANLE is recognized for having the most complete families of bottles and jars, from the smallest sample sizes to one-liter options, and many sizes in between,contact us to know more!